1, 12 station disc type ball bubble total installation

2, the equipment to complete the function: human tooling lamp holder feeding – automatic line cutting – automatic measurement of

bright bending – defective products automatically pick out -E26/27 automatic drawing pin – automatic riveting 12 needle –

automatic ball foam – automatic ball foam – good products automatic blanking.

3, automatic brightness detection need to detect the current, voltage, power, power factors, defective products should also be

judged and removed from the current, voltage, power, power factors.

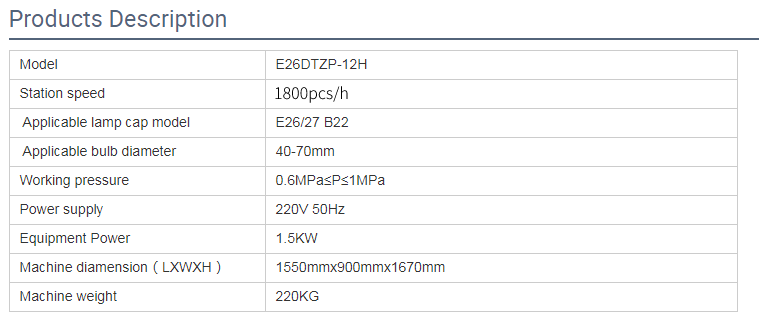

Application: This product is a new model developed by our company according to the standard specifications of domestic and foreign bulb lamps. This product is mainly used in bulb lamp assembly line. The main processes include automatic light source board pressing and bulb assembly. Fits E26 / 27 lamp holders.

Feature: The two types of equipment are mass-produced, reducing transfer links, high production efficiency, and high product qualification rate. The equipment can be split according to production needs to achieve flexible production methods. The equipment has an independent control system to avoid equipment failure, and two equipment will be shut down at the same time. Note: out-of-range dimensions can be customized.