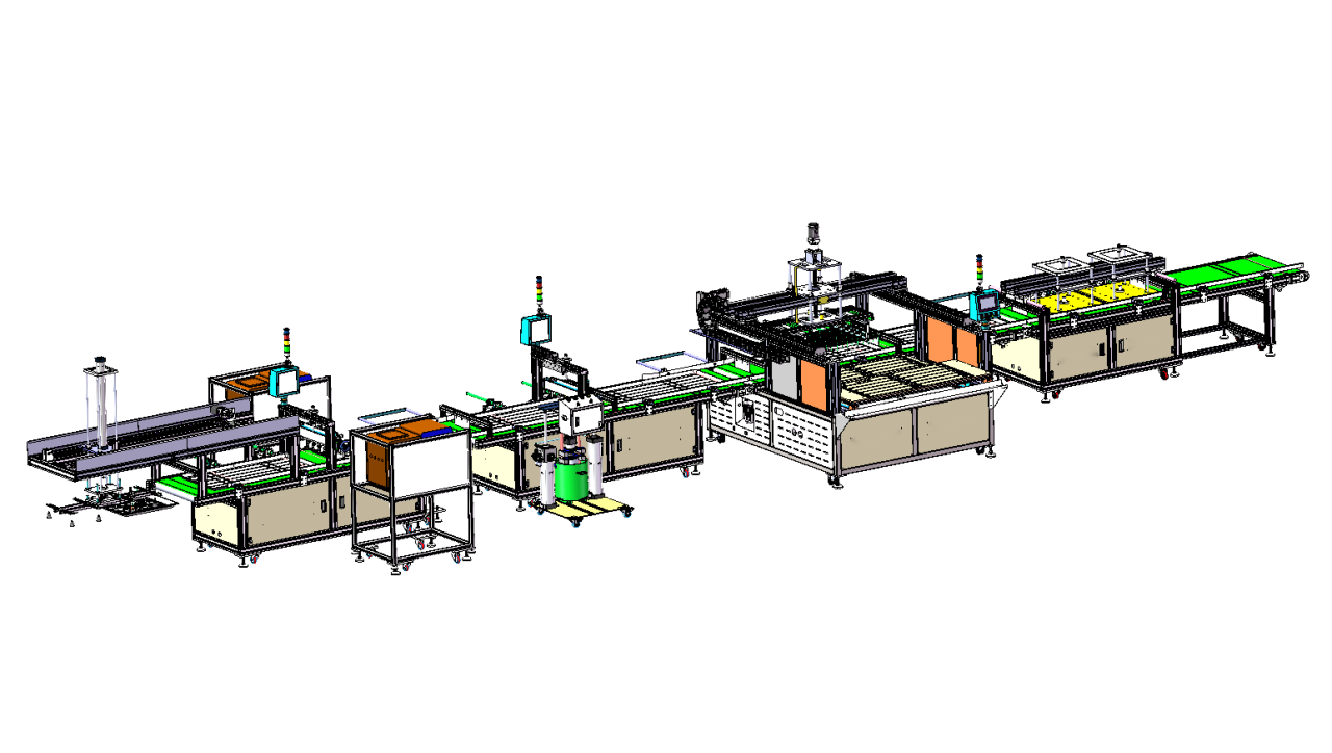

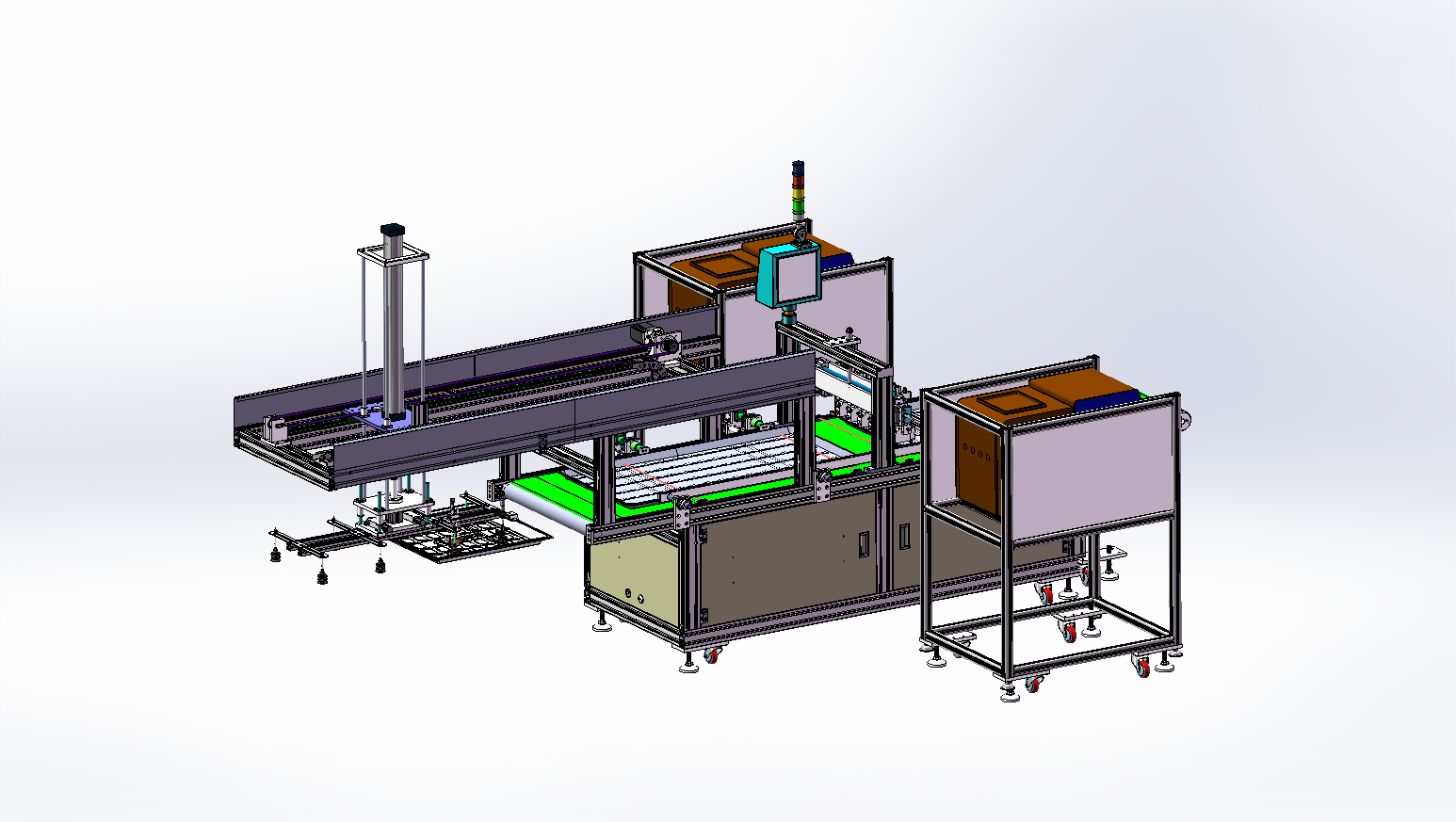

Device overview:

The equipment is divided into four modules, with the chassis transported on a PVC belt and positioned through a stopper and a tapping edge; The bottom of the equipment is equipped with universal casters and adjustable foot cups, making it more convenient for customers to layout and move their workshops; There are three upper level workstations, with a design speed of about 20S and a single hour output of 180PCS; The personnel requirement for the entire line (including packaging) is 29 people; The following are the station processes of the equipment: 1. Automatic chassis launch (single disc) 2. Automatic silicone 8-point adhesive valve 3. Manual lighting strip automatic fitting 4. Automatic pressure maintaining; 5. Manual belt assembly 6. Automatic locking screw 7. Artificial aging rack Manufacturing specifications: Voltage: AC380V/50~60HZ three-phase five wire system Air pressure: 0.5~0.7MP Equipment meets national safety production standards

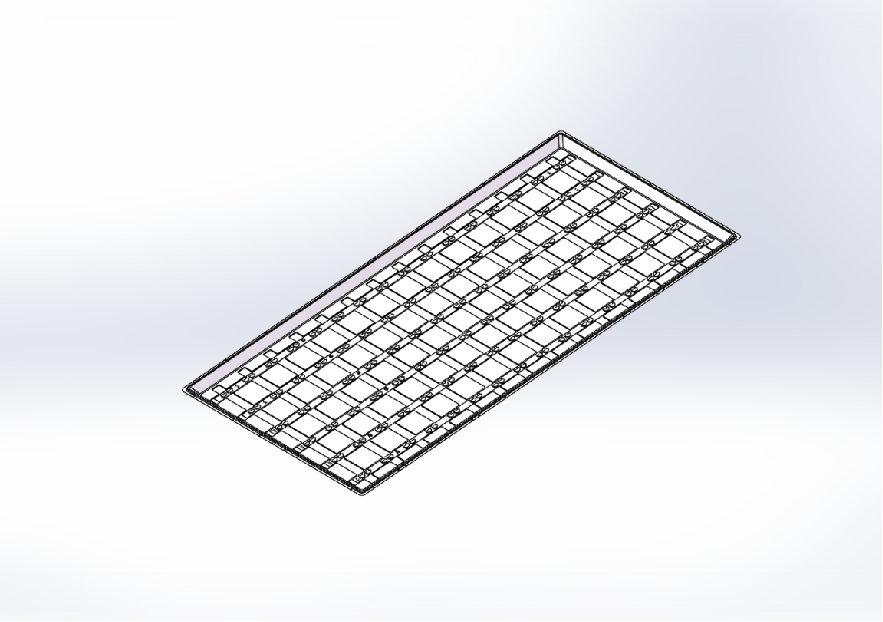

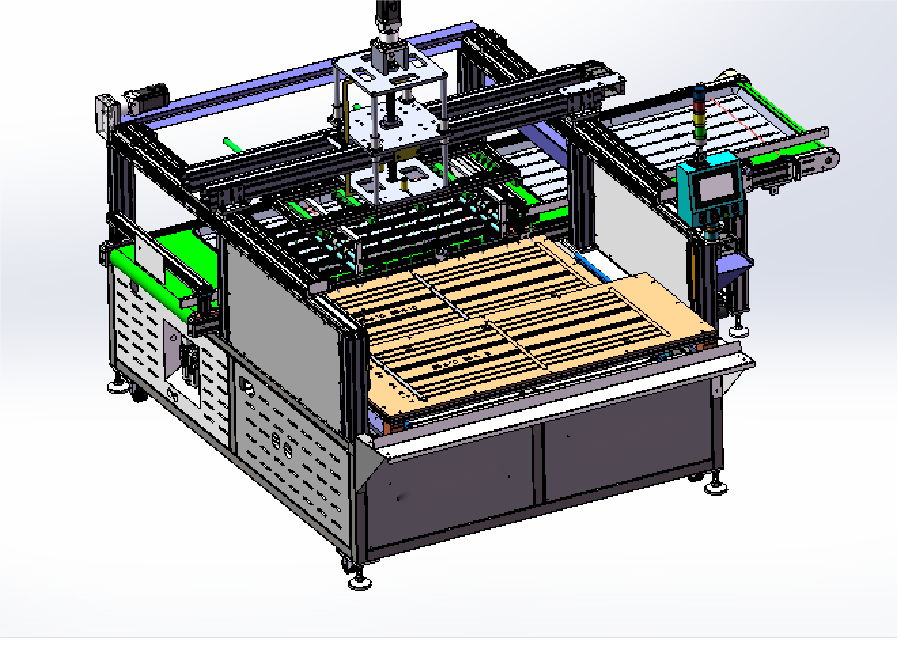

Panel light structure:

1. The gluing equipment consists of eight nozzles with a spacing of 68, and is adjustable and compatible with products with a spacing of 96.2 and 88 for six light strips. The spacing of the glue valve requires quick adjustment. 2. The corresponding light strip fixture needs to be equipped with an independent model, and each light type fixture can complete the entire product use.

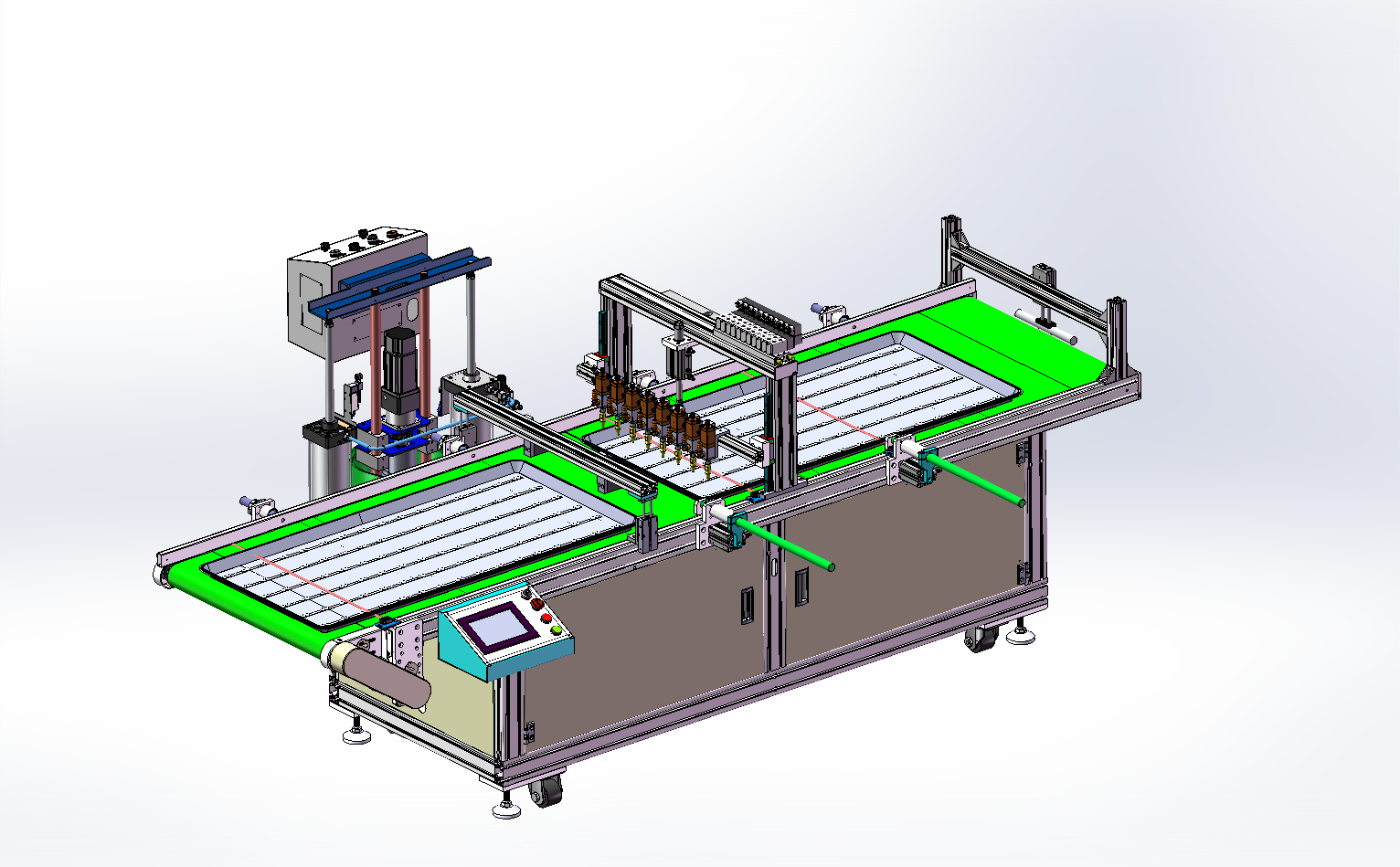

Automatic feeding point Hot-melt adhesive:

Equipment Description 1. Feeding mechanism The suction plate adopts a cylinder up and down mechanism, and the suction plate part adopts a shaking cylinder MA16 * 25 to prevent the bottom shells of the two panel lights from sticking together; 2. Spot silicone 8 glue guns and apply Hot-melt adhesive at the same time.

Automatically points silicone gel:

Equipment Description 1. Feeding mechanism The suction plate adopts a cylinder up and down mechanism, and the suction plate part adopts a shaking cylinder MA16 * 25 to prevent the bottom shells of the two panel lights from sticking together; 2. Spot silicone 8 glue guns, simultaneously applying silicone, 5 gallon dispensing bucket.

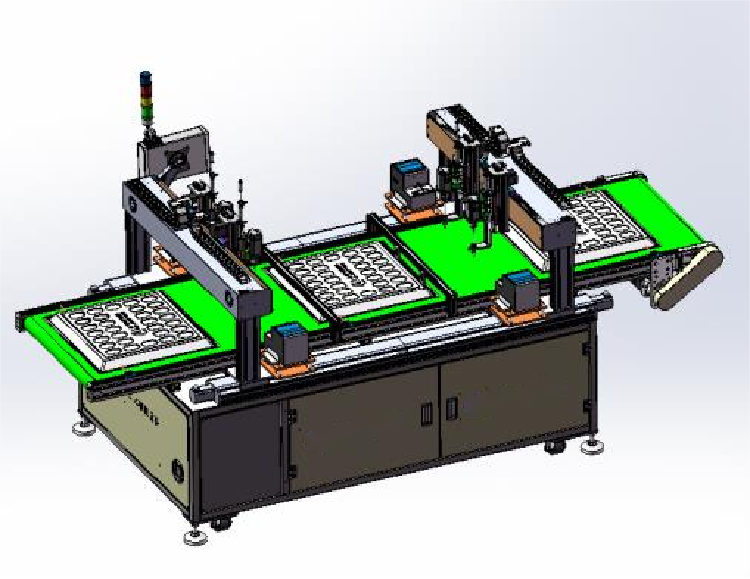

Automatic dispensing machine:

Equipment Description: 1. The automatically glued panel light automatically feeds the material to the bonding station 2. Adhere to the workstation and automatically suck away the light placed by the employee on the fixture and send it to the light board for attachment. The two fixtures are used alternately to save waiting time for manual swing. 3. The overall structure is directly supported by the gantry on the belt line, which ensures the stability of the entire machine, ensures parallelism, and is easy to adjust by changing the line and adjusting the level. And the operation is more stable.

| Parameter Description | |

| Name | Panel lights are glued onto the flow line |

| Glue supply system | 2600MLGlue supply bucket(2PCS) |

| pressure | 6-8PA |

| way of working | Automatic product loading, sensing of product, automatic gluing, automatic bonding,

automatic bonding and pressure maintaining, automatic lowering of lamp panel |

| Product specifications | LED panel lights with adjustable sizes from 600 to 1200 |

| operating mode | 7-inch touch screen |

| Power | Micro motor adjustable from 0 to 10 meters |

| Rack | Assembled with 40X80 aluminum profile, welded with 50 square joints

at the fitting station, powder sprayed |

| Belt | Green anti-static PVC belt with a thickness of 2.0 |

| Dispensing component | 8 dispensing valves for simultaneous dispensing, which one to

choose and adjustable position |

| Module | Linkage belt module |

| Transmission mode | Servo motor+belt |

| Power supply | AC380V/50Hz |

| Vacuum pump | 3KW, 100 cubic meter vacuum pump (more stable vacuum, low sound,

different from other circular negative pressure fans in the industry) |

| Size | L9000×W2100×H1800MM,3m for each section, aviation plug docking. |

| PLC | Maintenance and control |

| Gluing efficiency | 280PCS/H,(600MM panel 240PCS/H,1200MM panel 200PCS/H) |

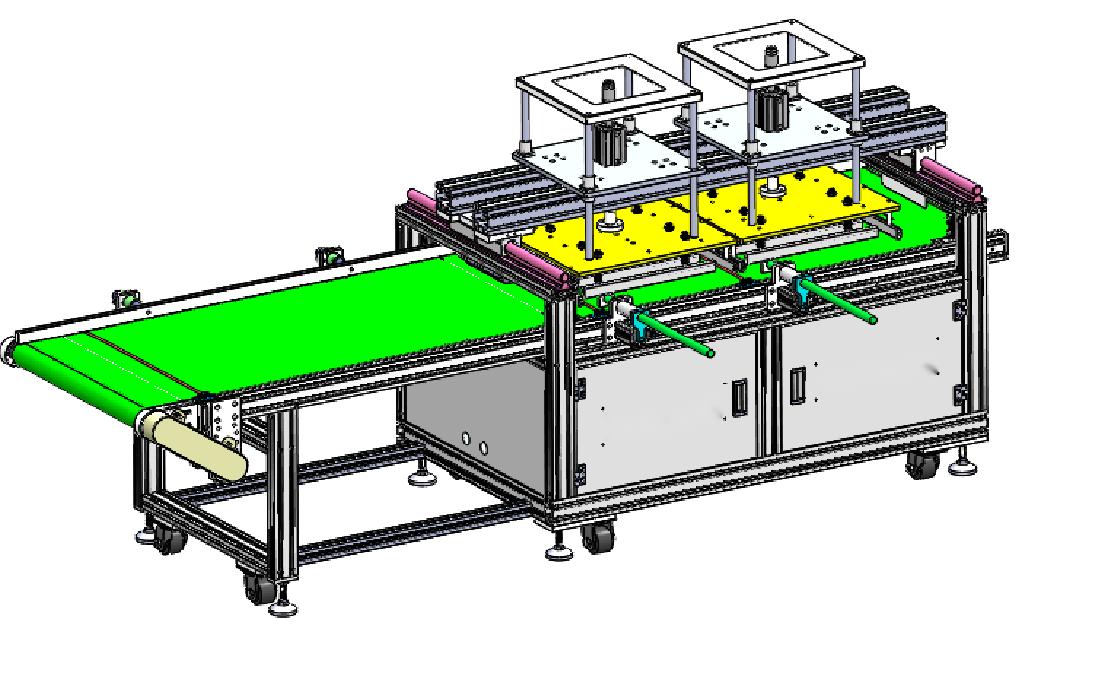

Press machine

Panel light four head locking screw machine:

Equipment Description: 1. It adopts 400W servo with torque control and is compatible with panel lights of sizes 300 to 1200, 2. Using a screw arrangement machine to arrange screws and a suction type automatic locking screw 3. Double head double feeder has fast and more stable speed; 4. Add button switches on both sides; 5. 600 * 1200 production capacity: 2 seconds/1 screw.

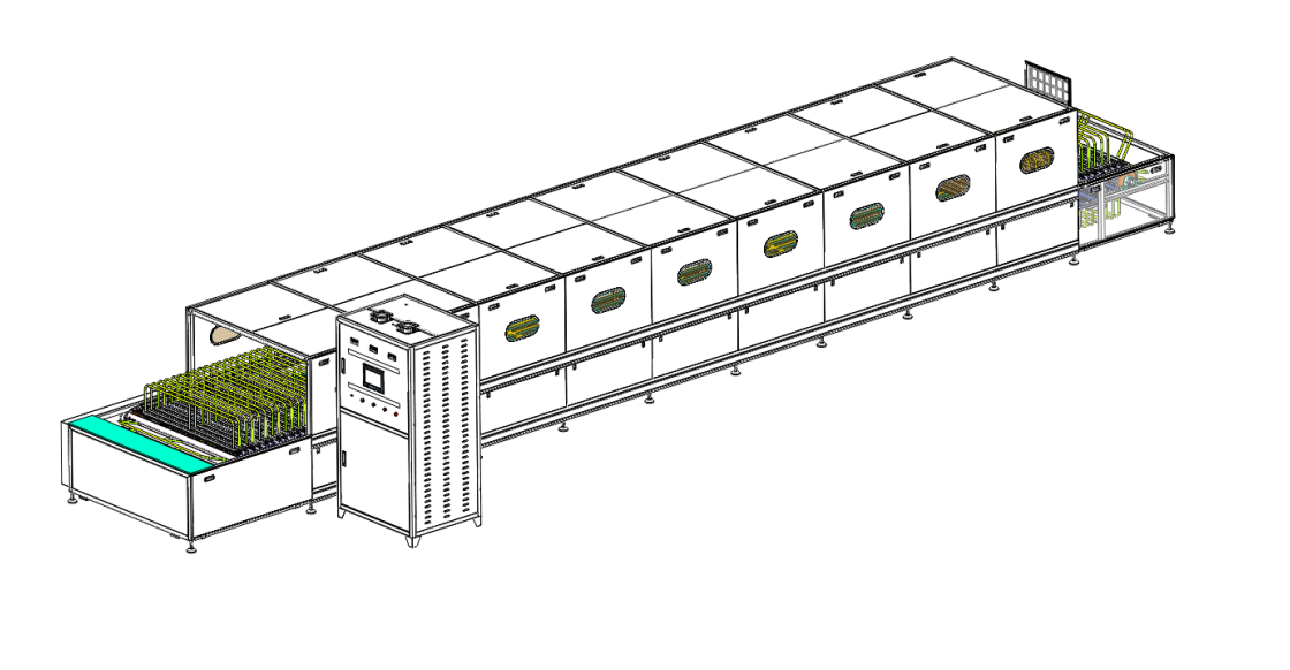

Aging line:

Technical requirements: 1. Power: Equipped with a 2.2KW gear reduction motor, a 3HP frequency converter, and an adjustable linear speed of 0-3M/min. 2. Rack: The rack is made of 40 * 40 T=1.5 steel pipe welded, and the body is made of 130 * 23 * 2 edge protection aluminum material. The protective plate is made of 1.2 cold plate bending, and the support legs are equipped with galvanized adjustable foot cups. 3. Conveyor chain: C2060 single sided ear double pitch double hole chain produced by Hangzhou Chain Factory is used, 4. Chain plate: Made of 2.0 hot-rolled plate bent into 148 * 1490 * 15mm, with a total of 130 pieces (only the upper layer) and 65 pieces, each plate equipped with 4 speaker clips; Equipped with small circuit breakers; Install two conductive systems at the bottom of the chain plate, each with two conductive copper steel brushes, and a total of two for each plate. 5. Daily production: This aging line can accommodate 600 * 600=260 panel lights, 600 * 1200=130 panel lights, and the aging time is calculated based on 60 minutes. 6. Light and dust cover: A sealed light and dust cover is installed on the surface of the line (excluding areas without electricity at both ends) to prevent dust from entering the main body, effectively attenuate aging strong light, and better protect the eyes. The door can be opened to check the aging status; 7. Conductive groove: Two conductive groove rails are equipped offline for the entire line, using high-quality epoxy resin board high-strength insulation rubber pads, and equipped with 1.5mm * 20 * 50 stainless steel aging dedicated conductive rails 8. Detection of beat (impact) circuit: Any area is the control area for the aging of the shooting lifespan. Adopting digital display time relay control, with adjustable off time and variable voltage output. 9. Full line voltage zone: One low-voltage zone A: equipped with one 10KW-250V self coupling Pressure regulator One atmospheric pressure zone B: equipped with one 5KW-250V self coupling Pressure regulator One high-voltage zone C: equipped with one 5KW-300V self coupling Pressure regulator One impact zone D: equipped with one 5KW-300V self coupling Pressure regulator There is one Pressure regulator for 10KW and two Pressure regulator for 5KW. There are four zones in the whole line. If the voltage aging mode is changed, manually adjust the Pressure regulator; 10. Full line power output: 35KW/220V; The actual power consumption depends on the customer’s aging products and quantity. 11. Electrical control: voltage and temperature control indicators are displayed digitally. The whole system is controlled by PLC and touch screen. There are 4 Pressure regulator and 1 distribution cabinet. 12. Body color: The entire chain board is sprayed with white plastic, the aluminum alloy profile is the original color, and the rest is computer white.